How to Clean the Nozzle on Your 3D Printer

Whether it’s clogged or you just want to take good care of it, knowing how to clean your 3D printer nozzle is important. Let’s walk through a few methods.

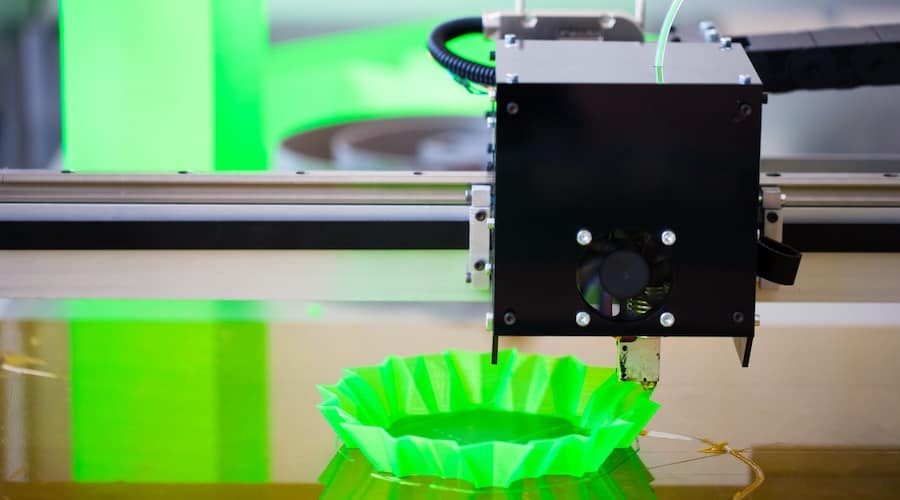

Welcome to the whimsical world of 3D printing, where the humble nozzle reigns supreme! This tiny titan is the star of the show in fused deposition modeling (FDM) 3D printers, acting as the magical pen tip that draws your 3D fantasies into reality. It melts and extrudes the filament with precision. Sometimes, though, you’ll experience a clogged nozzle. Then it’s like having a pen run out of ink, ultimately bringing your printing projects to a screeching halt. Let’s dive in and learn how to clean that vital nozzle on your 3D printer.

Methods to Clean a 3D Printer Nozzle

Exactly how you should clean your 3D printer’s nozzle depends on how badly it’s clogged. This could be a partial clog, which will allow some filament to extrude but could really mess up the supports for your build. Or, it might be a full clog — you’ll see your print head going back and forth but not leaving any filament behind.

First, though, you might need some tools to really get the job done. Here are a few items that could definitely help get your clog cleared and your 3D printer purring like a kitten once again.

Amazon.com Price updated on 2024-01-18 - We may earn a commission for purchases using our links: more info

When Your Nozzle’s Just a Little Clogged

If you’ve only got a partial clog, you should be able to take care of it with cleaning filament or a wire brush.

Cleaning Filament to the Rescue

Your first step to clean the nozzle on your 3D printer should be to use a cleaning filament. This isn’t your average plastic filament. Instead, it’s like the superhero of filaments, dedicated to cleaning, not printing.

- Following the instructions for your particular 3D printer, heat the nozzle a tad hotter than your last print job (but not too hot, or you’ll have a filament BBQ inside the nozzle).

- Feed the cleaning filament until it comes out cleaner than a whistle.

- If the clog wasn’t too stubborn, your printer is back in business!

Bringing In the Big Guns or Brushes

If your nozzle looks like it rolled in a pile of melted filament, you may be able to fix it with a brass wire brush. Please don’t use a steel brush, though, as it could scratch your precious nozzle).

- Heat the nozzle to around 220º C, then gently scrub the gunk away. If you’ve been using filament with a higher melting point, heat the nozzle to about 10º hotter than that temperature.

- For the stubborn bits, an alcohol wipe can be your secret weapon.

- Let your nozzle cool down, then run a test print to see if the nozzle is clear.

When the Nozzle Is Fully Clogged

Of course, sometimes the clog will be much more severe. If it’s fully clogged, you’ll notice that no filament gets extruded at all. Not all is lost, though. There are four tricks you can try to clean that 3D printer nozzle and get yourself back in business.

The Needle Trick

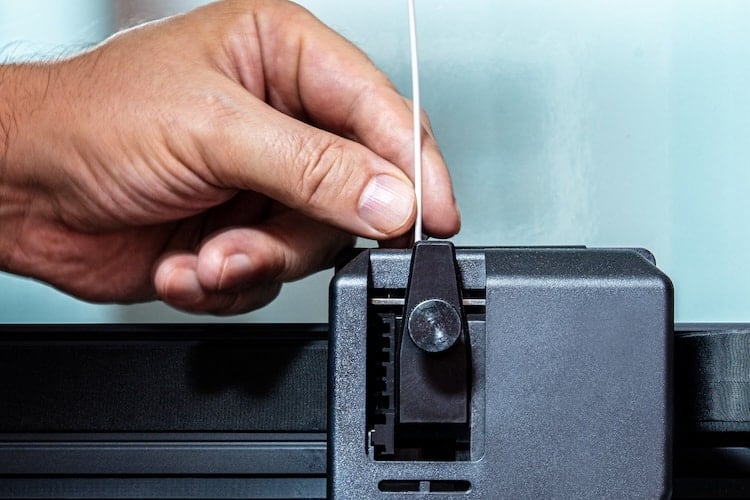

The first thing to try for a full clog is needle time.

- Heat your nozzle to whatever temperature you used for the last material you 3D printed.

- Gently poke upwards through the blockage with a needle finer than the nozzle itself.

- Your printer may have come with precisely the right tool for the job. Otherwise, an acupuncture needle or a guitar string will work. Be delicate — we’re not drilling for oil here.

Cold Pull, the Cool Way

For the cold pull method, you’ll aim to get all the material in the clog slightly detached from the nozzle walls.

- Heat the hot end to about 250° C. If you’ve been using PLA, heat it to 200° C.

- Push the filament through the print head.

- Let the nozzle cool, and your filament solidify.

- Next, reheat the nozzle to a lower temperature, like 115º C. When the temperature hits 90º C, quickly yank the filament up and out of the nozzle.

- If you see a filament tip shaped like your nozzle’s inside, you’ve nailed it.

This gets the particle buildup inside the nozzle to adhere to the filament as it solidifies. You may need three or four cold pulls to clean the nozzle completely. As a final tip for this method, make sure you’re using a soft filament like nylon.

Atomic Pull, the Hot Cousin of Cold Pull.

The cold pull method has a cousin, the atomic pull. This method keeps the heat on as you try to clear the blockage.

- To begin, remove the original filament.

- Heat the hot end to 220º C for PLA or 250º–260º C for harder materials.

- Once the nozzle is heated, manually feed the new filament until it extrudes.

- lower the heat to 160º C for ABS or PETG filament. For PLA, lower the temperature to 90º C.

- Once the nozzle is at a lower temperature, tug the filament out of the top.

As with the cold pull method, you know it’s done the job when the end of the filament looks like the tip of your printer’s nozzle.

Acetone, the Last Resort

If all else fails, it’s time to give your nozzle a spa day in an acetone bath (or ethyl acetate for the PLA folks).

- Remove the nozzle from the hot end following the method for your particular 3D printer.

- Submerge the nozzle in the acetone or solvent for a few hours.

- After 2–3 hours, removing whatever filament particles are left using a needle should be easy.

When All Cleaning Efforts Fail

If you’ve gone through all the methods above and still have a clog, it might be time to replace the nozzle altogether. Most 3D printing gurus say it’s best to replace the 3D printer nozzle every three to six months anyway.

Follow the manufacturer’s instructions to heat your hot end and remove the remaining printer. The heat will help make unscrewing the nozzle easier. Then screw the new nozzle onto the printer head.

Preventing Those Clogs in the First Place

Routine maintenance can help prevent clogged nozzles on your 3D printer. You need to do a clean-up job after every print to keep your nozzle pristine. That’s not all, though. Imagine your 3D printer is like a picky eater — it doesn’t like dirt and loves quality food (filament). Keeping it happy and clog-free is pretty easy if you follow these simple tips.

Keep It Clean

First off, let’s talk about cleanliness. Imagine your 3D printer lives in a bubble — you want to keep that bubble super clean. Dust off those surfaces, gently wipe your printer and treat your filaments like treasures.

Keep them in airtight containers with those little desiccant packets — they’re like tiny superheroes fighting off dust and dirt. Before you print, give your filament a quick spa treatment with a soft cloth or paper towel to brush off any pesky dust particles.

Quality Makes a Difference

Now, onto the filament — the printer’s food. Quality matters! Think of low-quality filaments like junk food — they might do the job, but they’re not great for your printer’s health. These cheap options can be uneven and sometimes sneak in unwanted bits that can clog up your printer’s works.

It’s like finding a pebble in your sandwich — not fun! Stick to the good stuff, the reputable brands that promise a smooth and reliable print every time.

Establish Great Habits for Your 3D Printing

Last but not least, let’s talk about good habits. Each time you switch filaments, think of it like changing courses in a meal — you’d want to clean the plate.

Do the same for your printer’s nozzle. Like when you’re cooking a gourmet meal, ensure you have the right temperature and settings for the filament you’re using.

Wrapping It All Up

These methods and tips give your printer the perfect conditions to create those awesome 3D prints. Remember all these suggestions, and you’ll be the best 3D printer artist around.

Leave a Reply

Leave a Reply